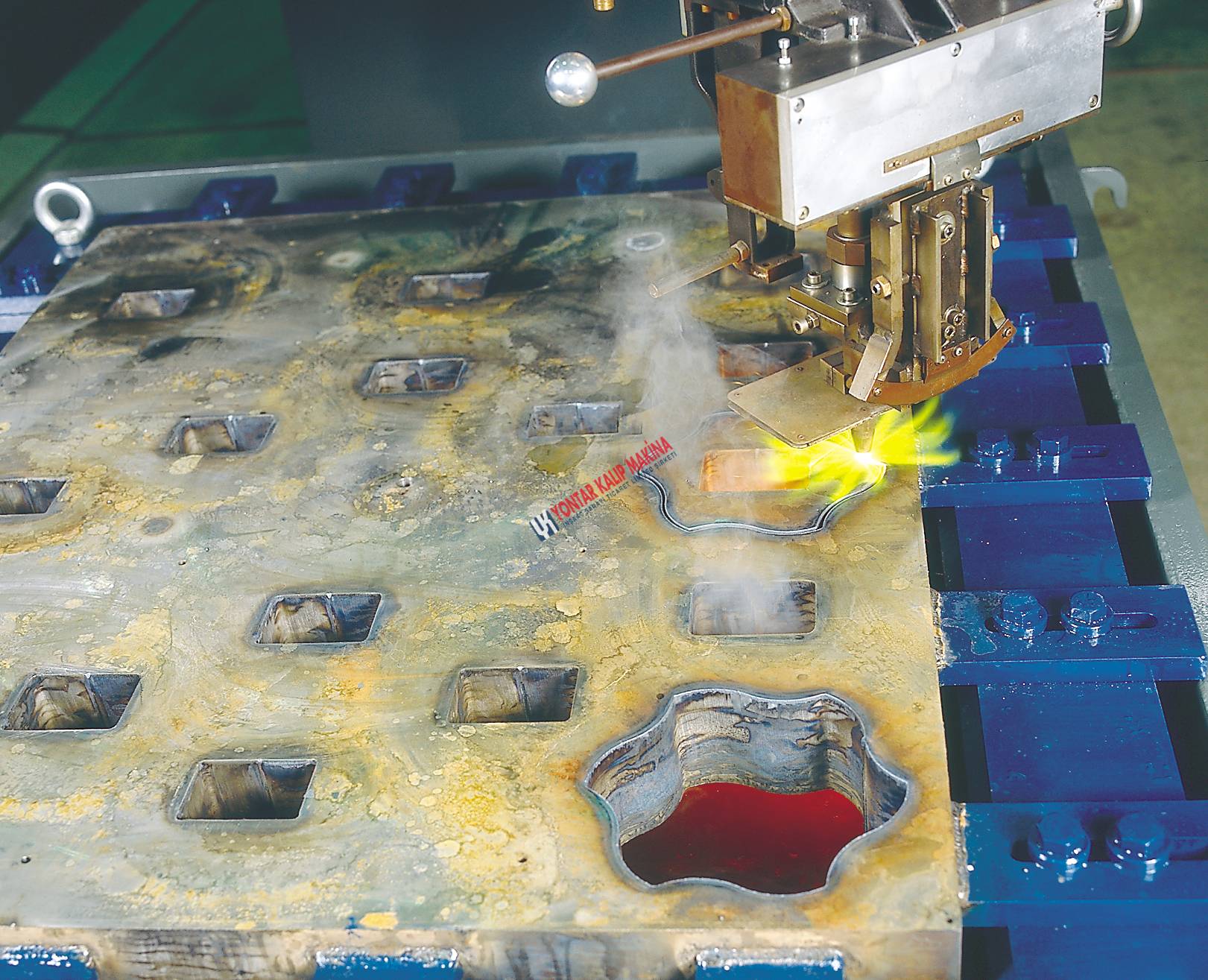

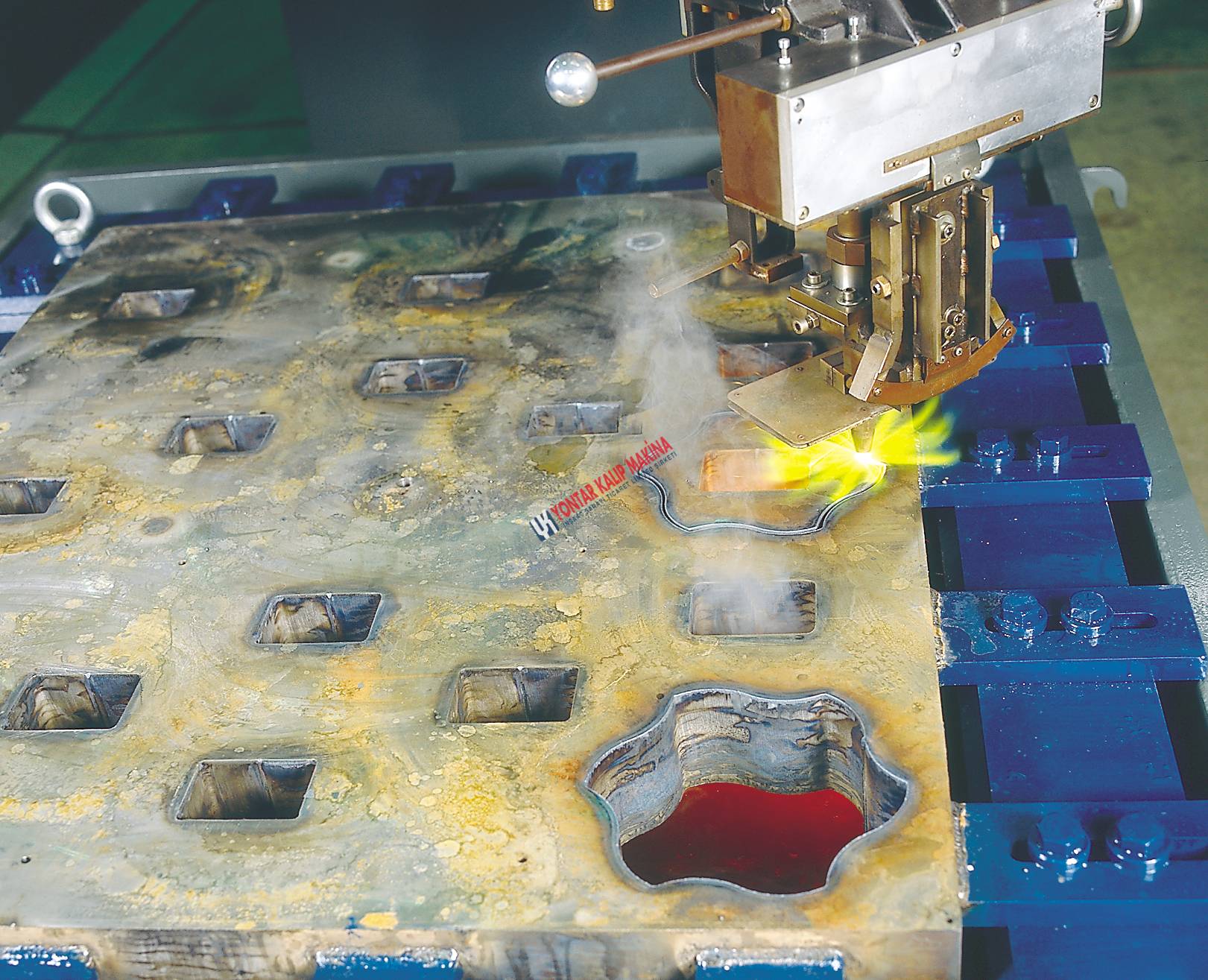

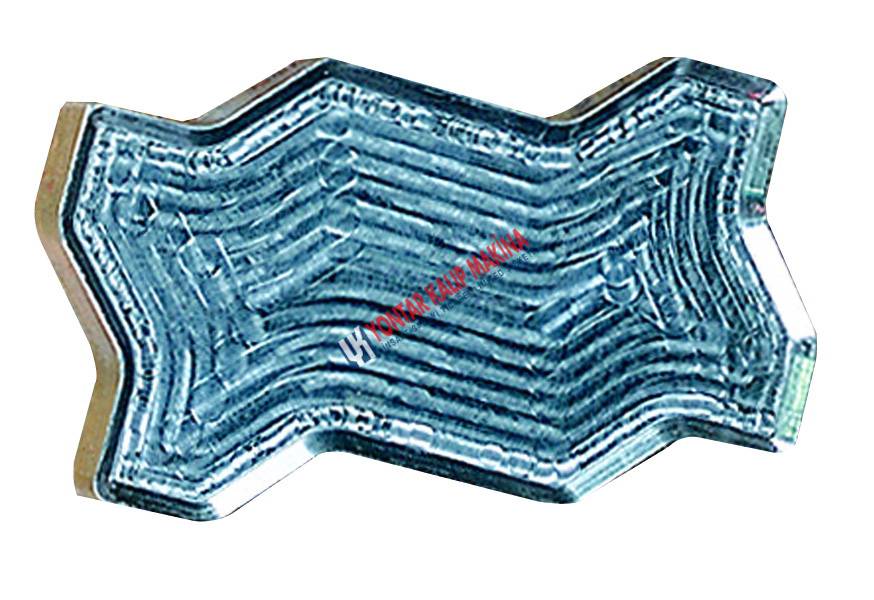

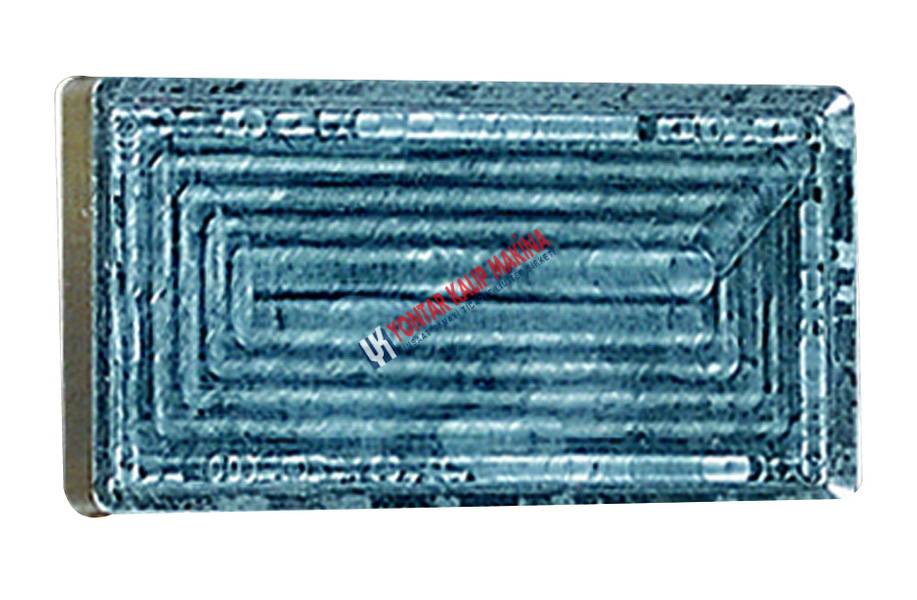

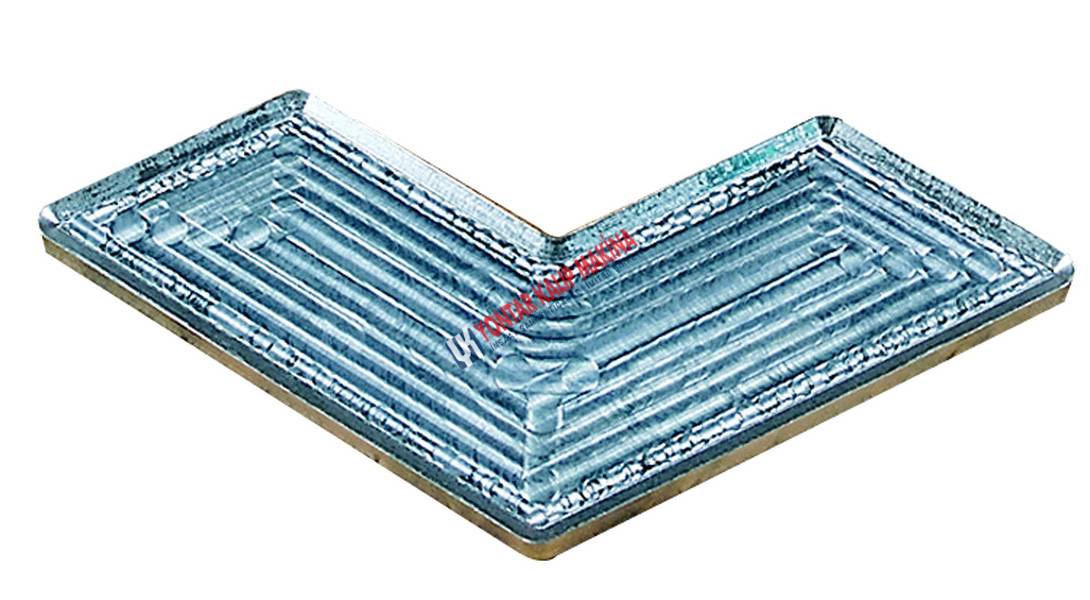

The monoblock frame moulds shared and shaped by means of oxygenation are manufactured with distinguished high class steels in a wide spectrum of patterns.

* Enables mould sharing in desired conicty by means of movable shearing torque with a rotation flexibility of '360°' sepcially manufactured for mould sharing.

* The monoblock moulds do not undergo power -degradation and preserve their stffness after oxygenated shearing.

* The monoblock moulds are more durable and no cracking occurs in female moulds.

* The mould design is effected under electronic means in every swift sequence.

* Superb quality is acquired through the utilization of advanced technology.

Every mould housing is scaled in coordinate- measuring machine.

The measurement data are serially transferred to the CNC central processing counters processing the styamping shoes. The measurement data are specifically numbered for every mould and saved in a computer. The same stamping shoes can repeatedly be processed according to such data when necessary.

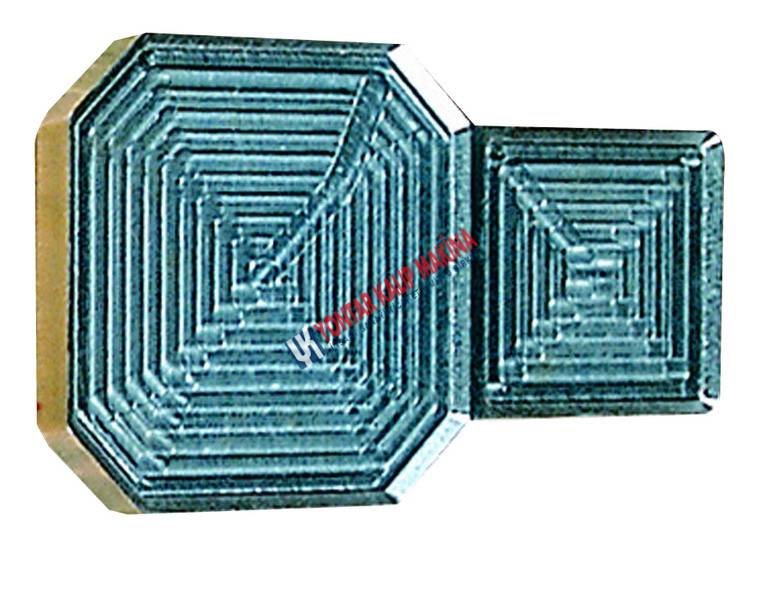

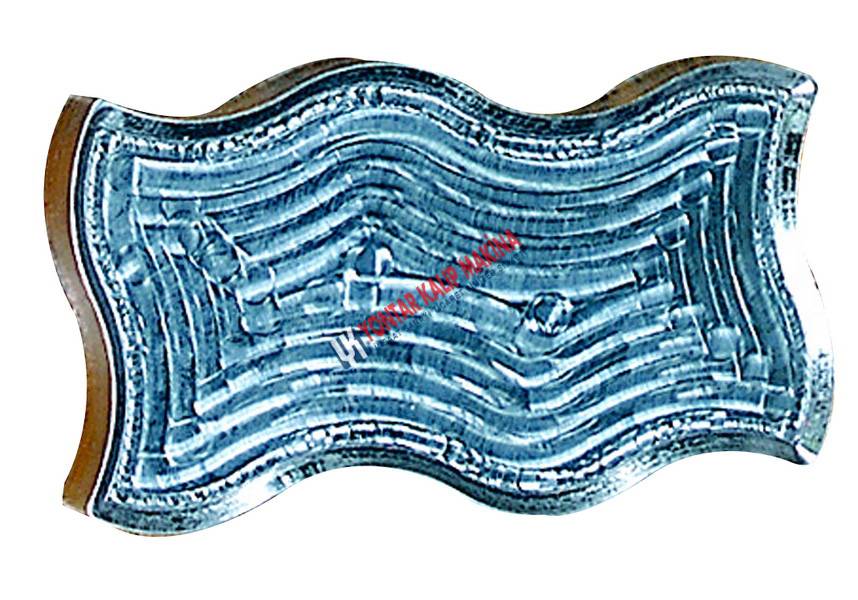

Stamping shoes are shaped at minimum spacing levels desired in CNC central proceesing counters in accordance with the measurement data from the coordinate measuring machine.

The inner surfacess of the stamping shoes are also processed at every sensitive surface quality in the CNC central processing counters.

Each stamping shoes is subjected to a special stiffening treatment.

With our experienced staff and extensive machinery park, we are committed to bring solutions to your every sort of mould requirements regardless of the type and brand of the machinery employed.

In addition to every kind of concrete paving stone moulds, briquette, ceiling blocks, curbstone moulds and perforated grass stone moulds, dedicated mould designs are implemented for your sprcific demands.