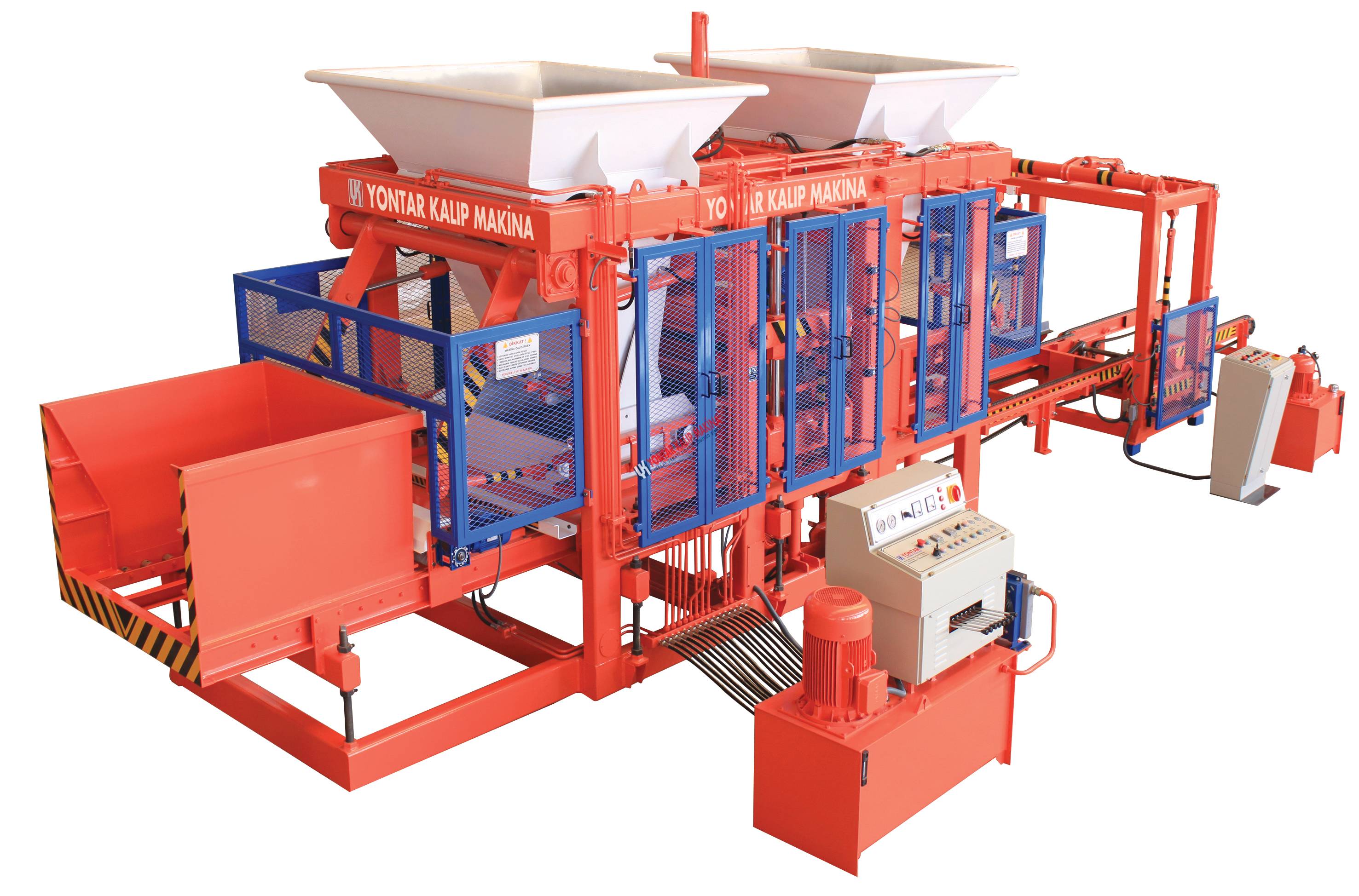

Oparetaes on hydraulic pressure and mechanical vibartion principle. The machine is employed in the manufacture of the prefabricated concrete elements such as interlocking or not-interlocking paving stones, grass stones, concrete curbstones, rain gatter stones, briquette and ceiling blocks.

KPM 25 is manufactured with two built -in mortar bunkers and a stacking robot. The system with double bunkers leads to evener smoother and colorful type surfaces as well as contributes to saving on the consumption of concrete dying paints.

When necessary or demanded, by means of putting the thin mortar station (front station) out of operation, single type aggregated and single -stamping manufacture may be effected.

In single or double -bunker KPM 25 concrete block making machines, in case the stacking robot is not requested by the customer,a 4000 mm product output band is installed to the front of the machine and a hydraulic handling tray is offered together with the machine.

| Type of Operation | Manual | Max.Length | 12200 mm |

| Max.Width | 2200 mm | Max.Height | 3450 mm |

| Max.Product Height | 300 mm | Min.Product Height | 50 mm |

| Pallet sizes | 950 x 1150 mm | Hydraulic tank kapacity | 230 ltr. |

| Hydraulic flow rate | 64 ltr./min | Cycle time | 45 ÷50 sec. |

| Volume of Morta Bunker | 2x1200 ltr. | Number of bottom vibrators | 2 pcs. |

| Number of top vibrators | 2 pcs. | Total electric power | 21,5 Kw |